One Source for Scale Dealer Solutions

Our one source approach gives us the ability to customize the equipment and systems you require, as opposed to an “off the rack” answer. With our large product line, our in-house engineers are able to design and assemble complete systems to meet your specific manufacturing needs.

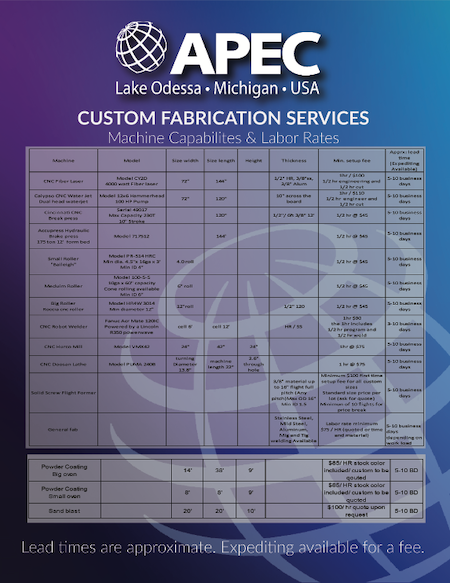

Major Scales

- Conical and rectangular scale hoppers

- Capacities from 17 to 368 cu ft and from 0.15 to 5 tons

- Slide gate, butterfly valve or knife gate discharges

- 60 degree angle design

- Flanged inlet and outlet

- Solid bolted top cover

- Load cell mounts

- Summing box

- Carbon steel or stainless steel construction

Minor Scales

- Conical and rectangular scale hoppers

- Capacities from 10 to 35 cu ft and from 0.1 to1 ton

- Integral ingredient hoppers sizes from 25 to 100 cu ft

- Slide gate, butterfly valve or knife gate discharges

- 60 degree angle design

- Flanged inlet and outlet

- Solid bolted top cover

- Load cell mounts

- Summing box

- Carbon steel or stainless steel construction

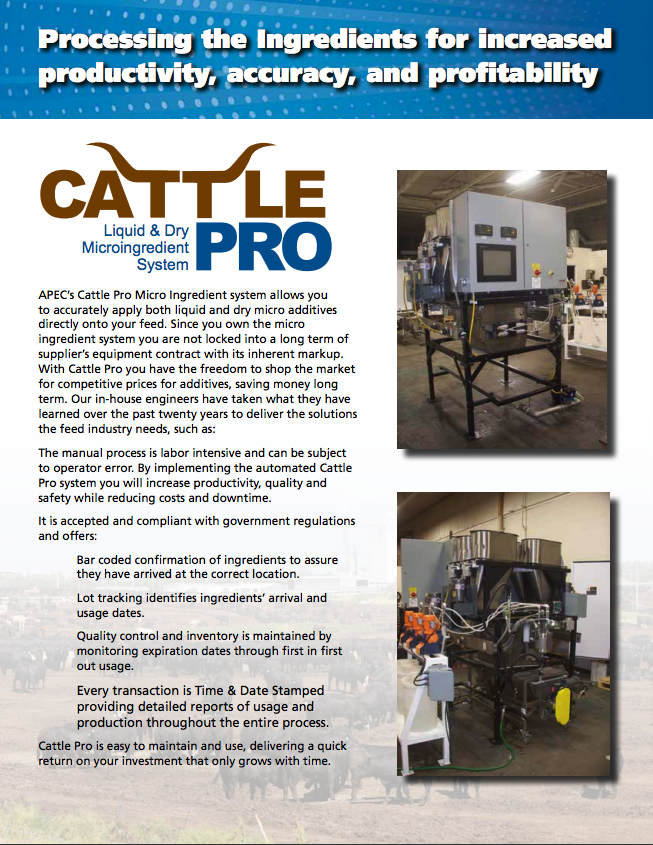

Micro Scales

- Conical, rectangular and roll over scale hoppers

- Capacities from 2 to 20 cu ft cu ft and from 25 to 250 lbs

- Integral ingredient hoppers with feeders and mechanical agitation from 5 to 35 cu ft

- 矩形或圆形本clusters

- Indexing scale that travels under the individual feeders

- Slide gate, butterfly valve or knife gate discharges

- 60 degree angle design

- Flanged inlet and outlet

- Load cell mounts

- Summing box

- Carbon steel or stainless steel construction

Weigh Screw Feeders

- Continuous flow measurement

- Flow rates from 250 to 6000 cu ft per hour with a turn down ratio of 5:1

- Accuracy of the feeder is +-2% full scale on virtually all free flowing solids with a wide range of densities

- Cantilevered screw feeder with pivot centered under the feeder inlet

- Feeder suspended from a load cell hung from the discharge end

- 艾娃ilable with close tolerance construction of the feeder

- Low RPM

- Floor or ceiling mounted support frame

- Flanged inlet transition with flexible connector

- Load cell with mounts

- TEFC motor with gear/belt reducer

- Mild steel or stainless steel construction

Weigh Belt Conveyor

- Continuous flow measurement

- Accuracy of +- 2% of full scale

- Flow rates from 250-6000 cu. ft per hour with a turn down ratio of 5:1

- Cantilevered belt conveyor with pivot centered under the in-feed of the belt

- Conveyor suspended from a load cell hung from the discharge end

- Belt rides on a slider bed of 3 ply polyester with nitrile cover and hidden lacing

- Flanged inlet transition

- Flexible connector

- Adjustable bed depth gate, side skirting and scraper

- Hinged top cover

- Expanded metal bottom cover

- Outlet flexible connector

- Floor or ceiling mounted support frame

- Two load cells with mounts

- Summing box

- TEFC drive with gear/chain reduction and rotary encoder

- AC or DC variable speed drive

- Scale integrator

- Mild steel or stainless steel construction