Processing the Ingredients for Nutraceutical Success

Focused on solving your challenges

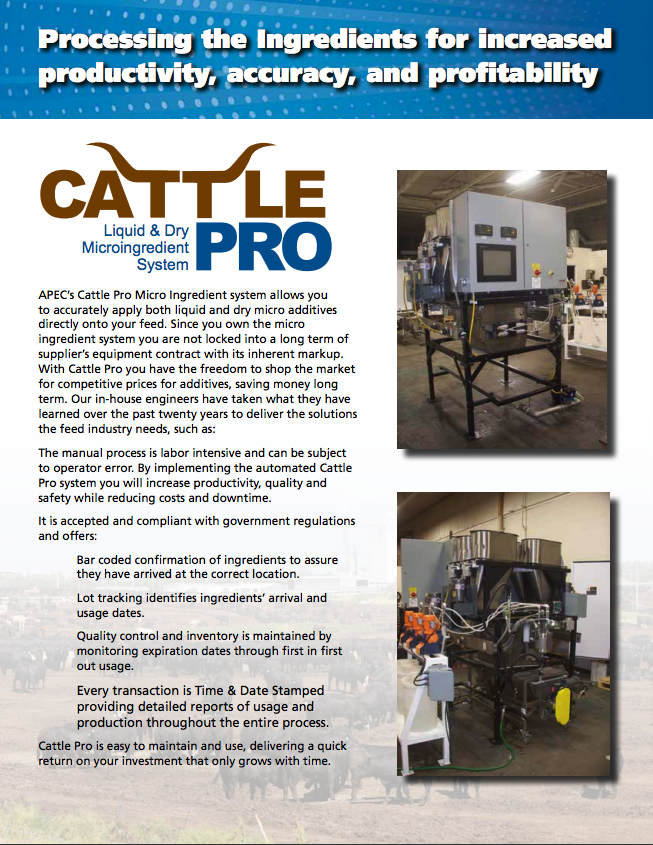

Since 1992, APEC has been developing the processing systems to improve performance for nutraceutical manufacturers. Whether it is standard equipment from our large product line or a customized processing solution, our customers have found APEC products will improve their bottom line. In the past twenty years we have learned what challenges the nutraceutical industry faces and our in-house engineers are focused on developing solutions to meet them, such as:

Increased accuracy and productivity

手动过程是劳动密集型的,可以ubject to operator error. A fully automated APEC system requires minimal intervention, resulting in increased productivity and quality with reduced costs.

Plant and worker safety is greatly improved through the elimination of repetitive motion and exposure to harmful chemicals. Your product safety is increased because of the systems ability to provide precise ingredient control.

Improved tracking and product safety

手册tracking and recording of your process is time consuming and prone to mistakes. Our equipment is accepted and compliant with government regulations. While you may maintain manual checks and balances if you wish, our automated system renders it unnecessary. It offers:

- Bar coded confirmation of ingredients to assure they have arrived at the correct location.

- Lot tracking identifies ingredients’ arrival and usage dates.

- Quality control and inventory is maintained by monitoring expiration dates through first in first out usage.

- Every transaction is Time & Date Stamped providing detailed reports of usage and production throughout the entire process.

- We conduct in-house product testing to assure your requirements will be met and you are welcome to join us for the testing procedures.

- Our automated systems deliver a quick return on your investment that only grows with time.