Snack Food Processing Equipment

With more than 30 years in the processing equipment business,APECknows and understands the challenges faced by the food industry. Our in-house engineers are committed to developing solutions to meet those challenges.

We’ve worked with a variety of industries with diverse applications like rubber products, cereal products,pet food, vitamin and mineral supplements, and more. We know how to adapt to the needs of our customers, regardless of the industry.

As snack food processing equipment manufacturers, we’ll help you improve your bottom line through efficient and smart products tailored to your industry and product.

We’re A Manufacturer That Provides Productivity, Quality, and Safety Improvements

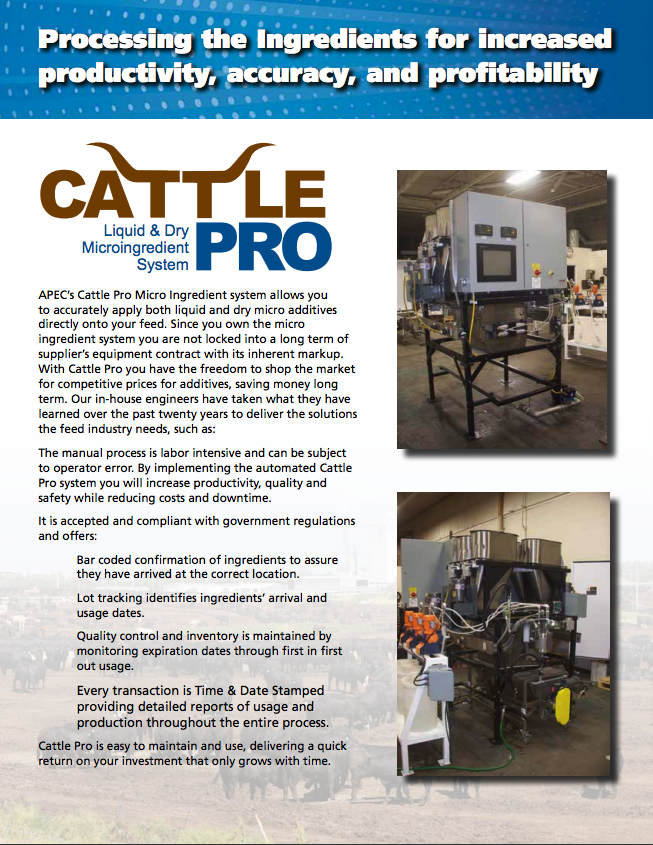

We’re committed to helping you increase productivity, quality, and safety in your operation. The APEC automated system removes the labor-intensive process involved in manual machines, which also removes the risk of operator error – helping your operation run more smoothly and efficiently.

In addition, our equipment delivers a nearly 0% breakage rate as a result of our close tolerance construction between mixing screws and trough. You can depend on our snack food processing equipment to help you meet your goals.

Improve Profit with Our Snack Food Processing Equipment

We understand the importance of your bottom line. The efficiency of our snack food processing equipment allows you to significantly reduce the amount of ingredients used in the coating process – while still producing the same quality product.

In addition, when you use our equipment, you can add acontrol systemthat removes the need for manual tracking and recording of your process – removing the chance of user error, as well as providing more time for your process.

Automation Pro

We know how crucial it is to meet FDA compliance. Our Automation Pro provides a control system to help you meet compliance requirements with:

- 酒吧是编码的确认edients to assure they’ve arrived at the correct location.

- Lot tracking to identify ingredients’ arrival and usage dates. The system keeps track of quality control and inventory by monitoring expiration dates through first in/first out usage.

- Time and date stamping – every transaction goes through a time and date stamping process to provide detailed reports of usage and production.

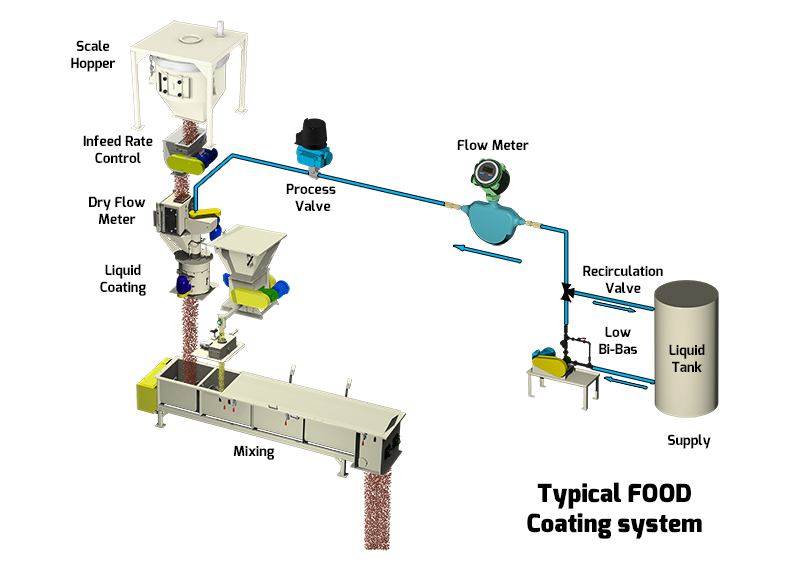

- The APEC Mistcoater –the perfect coating systemfor food processing.

Meeting Your Snack Food Processing Needs

We ensure your requirements will be met through our in-house product testing. We welcome and encourage clients to join us during the testing procedures so we can address any questions or concerns.

Choose one of our many machines from our large product line of snack food processing equipment, or work with us to create a customized processing solution tailored to your specific needs.

We’re constantly promoting innovation and the introduction of new products within APEC, and we’re certain we can find the right solution for your company.

8 Keys to Selecting the Best Dry Mix Equipment

From pancakes to protein powder, it’s important to select the right mixer options for your current and future needs.