Animal Feed Processing and Coating Equipment

Solving Problems for the Animal Feed Industry

Automated Process Equipment Corporation (APEC) has been developing better animal feed coating and processing equipment methods to help improve performance and production for animal and aqua feeds since 1992.

In addition to our superior animal feedprocessing systems, we also offerproduct control systemsthat work automatically and collaboratively with your animal feed equipment.

We have developed such integrative systems in order to offer a single point of responsibility, and in turn to allow for easier evaluation of quality and output. This unique structure delivers a complete solution that can better determine, consider, and subsequently meet the needs of your growing feed business.

Animal Feed Processing Equipment that Increases Accuracy and Productivity

Our systems deliver the constant cost cutting benefit of productivity that can be monitored effectively and consistently. Because of our intuitive monitoring processes, your business can begin reducing labor and error, and consequently improving your overall quality of product and customer satisfaction.

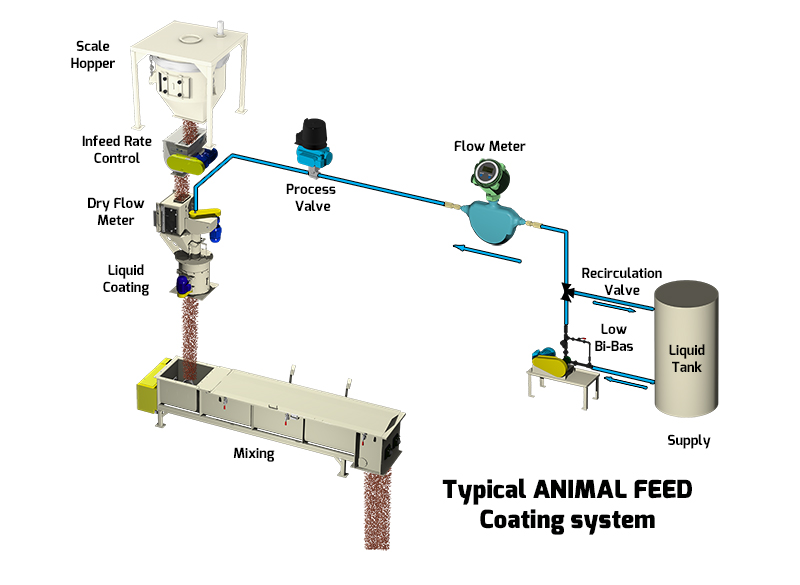

Although you may have delicate animal feed to process, and you might even have difficult coatings, these won’t be a problem for APEC’s automated process systems. Our animal feed processing equipment provides less breakage and more consistent liquid application than many other options available.

Our equipment can even improve PPLA (post-pellet liquid application) when applying micro liquids, such as enzymes and mold inhibitors during pelleting, as well.

Utilize one of our reliable and observable animal feedcoating equipment systems, and you won’t be the only one who notices the difference in end-product quality.

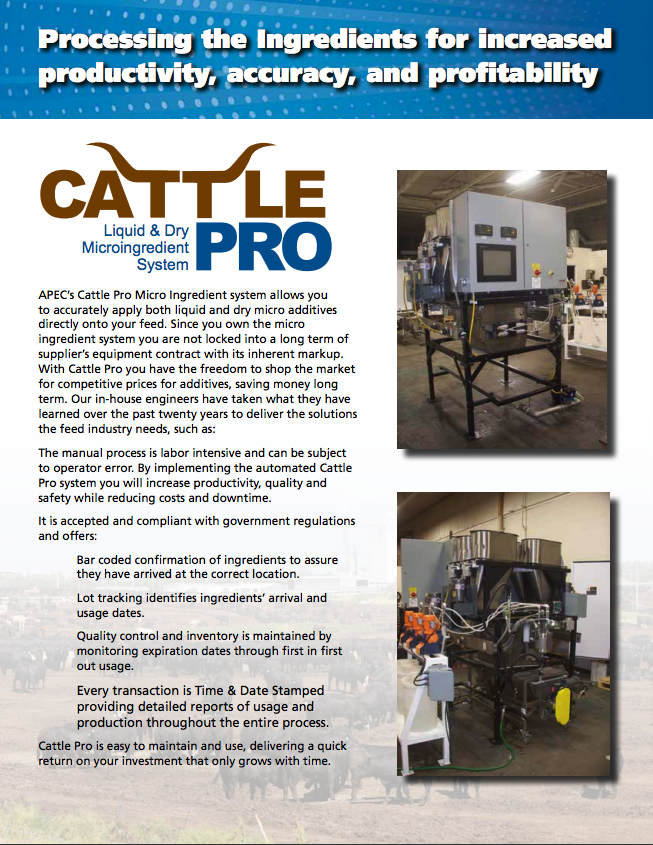

CattlePro Liquid & Dry Microingredient System

Accurately apply liquid and dry micro additives directly onto your cattle feed with the CattlePro Microingredient System—and take control of your bottom line. You’ll own the equipment and avoid being locked into a long-term contract and related markup.

Automating this part of the feed process will increase productivity, quality, and safety, while reducing costs and downtime. Standard features include bar coded confirmation of ingredients, lot tracking and usage dates, modular construction for maximum versatility, detailed usage and production reports, and many more.

Improve Tracking and Product Safety with our Animal Feed Processing Equipment

Our Automation Pro is a tailored control system capable of a variety of useful and effective processes to help ensure your feed productions go smoothly and efficiently. Some useful facets included are:

- The ability to precisely monitor and manage your processes as they occur.

- Durable and easily maintained components.

- Precise tracking to help meet FDA compliance standards.

- Bar code ingredient confirmation to ensure arrival at correct location.

- 很多追踪识别不啊nly the arrival, but also the actual usage of ingredients.

- Monitoring of expiration dates through a simple first-in-first-out usage tracking system.

- Easily maintained inventory and quality control capabilities.

- Time and Date stamping provided for each transaction.

- Ability to create a detailed report of usage and production outcomes.

Overall, our animal feed processing equipment, as well as our animal feed coating equipment, can offer a start-to-finish solution that can greatly enhance your current setup. Combine the correct method with a custom-made control system, and the result is a better product, a happier customer, and a more successful business.

Get More Information About Our Animal Feed Processing Equipment Today

Learn more about how APEC can help you to create a more successful business through building a better automated processing system.

Contact Usor call us at(616) 374-1000