Streamline Food and Beverage Processing and Production

Download the Executive’s Guide to Innovation in Food Processing

强g Automation to Improve Quality, Safety and Efficiency

Food processors face increased demands from both regulators and customers. Meeting these demands means harnessing innovation and making automation work for your facility. With the right automated equipment and supporting components, you can improve the speed, safety, and efficiency of your process. In the Executive’s Guide, we’ll show how automation can improve regulatory compliance, reduce downtime, keep employees safe, and improve product quality.

What is in This Guide?

![]()

Streamlining Production

Learn about manual processes you can easily remove to reduce downtime without disrupting your overall process or workforce.

![]()

Synchronizing Individual Processes

See how you can easily remove stops or slow-downs across the produce line by synchronizing machine run times and optimizing your equipment.

![]()

System Design to Simplify Traceability

强g your existing system and improvements, see how to automatically track and trace ingredients and shipments across the supply chain.

![]()

Reducing Liability

How automated systems reduce risks from foodborne illness, personal risks to workers, and regulatory risks from noncompliance.

Who Should Use this Guide?

Executives

Placing investment where it will yield the highest ROI requires careful consideration. It can be difficult to get all the information you need in one place. We wrote this guide to show what automation can do for your business, and how it can solve problems you may be facing.

Plant Managers

You want your plant to run smoothly. Reducing machinery slow-downs or stops, workplace safety incidents, and hazards means improving efficiency and making a better workplace for everyone. Use our guide to see how you can make automated equipment work for you, not against you.

Entrepreneurs

As an entrepreneur, you wear many hats. You know all about your product, how to run your business, set up your processing facility, regulations to follow, and how to do it all within your budget. Use our guide as a roadmap for implementing automation at your facility, so you can get the most benefits.

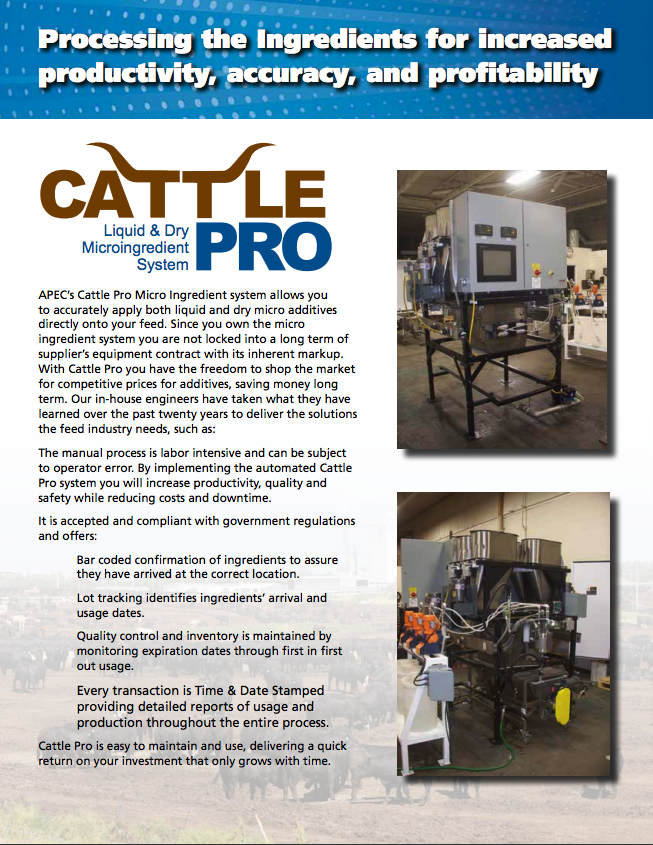

About APEC

Since 1992, APEC has specialized in the design and manufacturing of ingredient automation equipment and controls for weighing, dosing, mixing, continuous blending, and coating. Our equipment and control systems weigh and control flow rates from grams to tons. We serve a variety of industries with such diverse applications as the automatic formulation of flavored drink mix, rubber products, plastics, cereal products, pet food, animal feed, brake linings, vitamin and mineral supplements, lawn patch, fertilizer, foam, and composite wood products.