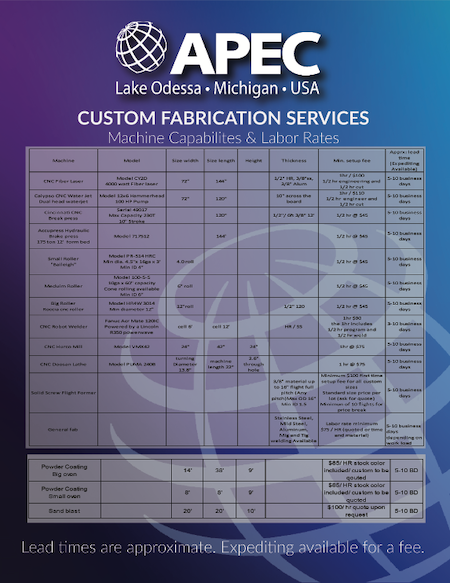

Batch Control System

Batch Control Advantage

Our batch control systems utilize off the shelf components for convenient service and repair.

- Designed for reliable operation

- Multi-tasking environment allows for simultaneously opened control screens

- Easily interfaced to windows systems

- Industrial computers for factory environments

- Easily expanded to multiple stations

- Remote access to applications from Windows systems via network

Real Time Graphical Display

看一眼:

-

- Formula is running

- Current ingredient being weighed

- Target weight and actual weight

- Desired mix time (wet and dry)

- Expired mix time

- 该队s of liquid pumps and the hand adds

- Devices shown on the screen change color as the status of each device changes

- Displays all alarm conditions

- Auto or “Point and Click” manual operation

- Communicates with other plant equipment/processes

- Device control eliminates custom program languages

- Device library for each device in the process

- Contains associated I/O points and parameters associated with equipment:

- Analog values for amps and speed

- Timing parameters for clean out, startup and shutdown

- Equipment sequence and process timing can be easily adjusted in the field without custom programming

- Easily support a variety of control algorithms such as loss in weight, PID loop control and rate control for ingredient hoppers and other transitional devices

Batch Control System Details

Standard Features

- PC Based

- QNX4 operating system

- Ethernet or fiber optic network

- Allen-Bradley or Opto22 I/O

- Ingredient and formula entry

Standard Features Cont’d

- Two available database choices standard Standard reports store 45 days of transactions

- SQL— Greater reporting capabilities store one year’s worth of transactions

- Report Generation Ingredient Usage Daily, weekly, monthly or custom

- Production totals—daily, weekly, monthly or custom alarms

- Production summary by batch or run

- Receipts

- 存储水平

- Lot tracking

Optional Features

- Barcode scanning for ingredient confirmation